Diving into the World of Rough Carbon Fiber Plates and Sheets

Carbon fiber has become a popular material in various industries due to its lightweight, strength, and durability. However, not all carbon fiber is created equal. One type that is gaining popularity is rough carbon fiber plates and sheets.

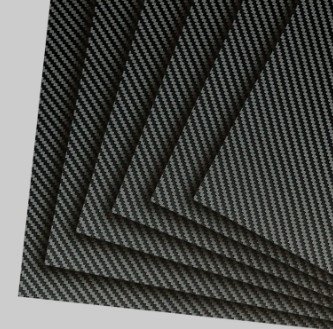

Rough carbon fiber differs from traditional smooth carbon fiber in its surface texture. While smooth carbon fiber has a glossy, polished finish, rough carbon fiber has a textured, matte finish. This texture is created by leaving the fibers in their raw state after they have been formed into Rough Carbon Fiber sheet or plates.

What Makes Rough Carbon Fiber Different

The main difference between rough and smooth carbon fiber is the surface finish. The rougher texture of rough carbon fiber can be attributed to the fibers being left in their natural state. This means that the individual carbon fibers are visible on the surface, giving it a more rugged and industrial look.

Moreover, rough carbon fiber is typically made from lower-grade carbon fiber materials. This may sound counterintuitive, as lower grade usually implies inferior quality. However, in this case, it simply means that the carbon fibers used are not as tightly woven together, resulting in a rougher surface texture.

Benefits of Rough Carbon Fiber

The unique texture of rough carbon fiber brings with it several advantages that make it a preferred choice for certain applications. These benefits include:

- Improved adhesion: The rough surface texture of rough carbon fiber provides better adhesion for glues and resins. This makes it an ideal material for use in structural applications where strong bonding is essential.

- Enhanced grip: The textured surface of rough carbon fiber provides a better grip compared to smooth carbon fiber. This makes it a popular choice for sporting equipment such as bike frames, golf clubs, and tennis rackets.

- Cost-effective: Rough carbon fiber is often cheaper than smooth carbon fiber due to the use of lower-grade materials. This makes it a cost-effective option for manufacturers and consumers.

- Unique aesthetics: The rugged, industrial look of rough carbon fiber sets it apart from the traditional smooth carbon fiber. This unique aesthetic appeal is desired by many designers and consumers alike.

Applications of Rough Carbon Fiber

Rough carbon fiber is finding its way into various industries and applications due to its unique properties. Some of its common uses include:

- Sporting equipment: As mentioned earlier, rough carbon fiber is ideal for sporting equipment due to its improved grip and strength. It is commonly used in the manufacturing of bike frames, golf clubs, tennis rackets, and even sports cars.

- Aerospace industry: Rough carbon fiber is also making a name for itself in the aerospace industry due to its lightweight and durable nature. It is used in the production of aircraft components, such as wings, tail units, and fuselage panels.

- Automotive industry: The automotive industry is another sector that has seen an increase in the use of rough carbon fiber. It is used in the production of lightweight and high-strength car parts, such as body panels and interior trim.

- Construction industry: Rough carbon fiber is also being incorporated into construction materials to make them stronger and more durable. It can be found in building structures, bridges, and even wind turbine blades.

Challenges of Using Rough Carbon Fiber

While rough carbon fiber offers many benefits, it also comes with its own set of challenges. One of the primary issues is the potential for increased wear and tear on tools and machinery. The rough texture of the material can cause abrasiveness, which may result in faster degradation of cutting and shaping tools. Additionally, the lower-grade carbon fibers used in rough carbon fiber can sometimes lead to inconsistencies in strength and durability, requiring more rigorous quality control measures during manufacturing. Understanding these challenges and addressing them effectively is essential for maximizing the potential of rough carbon fiber in various applications.

Conclusion

Rough carbon fiber may not have the same sleek appearance as smooth carbon fiber, but it offers its own set of benefits that make it a desirable material for various industries. Its unique texture, improved adhesion, and cost-effectiveness make it a versatile option for different applications. As technology continues to advance, we can expect to see even more innovations and uses for rough carbon fiber in the future. So, it is an exciting time to dive into the world of rough carbon fiber plates and sheets and discover all that this material has to offer. So, let’s get rough and explore the endless possibilities of this amazing material!